Types of Welded Cutting Tools

These tools are primarily used in precision machining, particularly suited for metal and mold processing that requires high accuracy. These welded carbide tools, thanks to the combination of welding technology and carbide material, are wellsuited to withstand high cutting pressures and meet the demands of extended machining operations, making them widely applicable in various precision component processes.

Below is a detailed introduction to each type of tool and its primary uses:

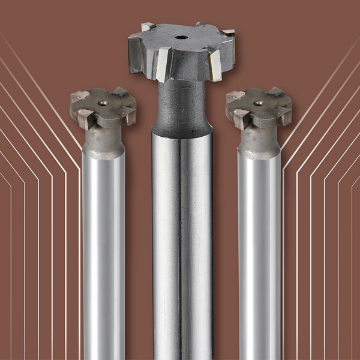

Welded Carbide TSlot Cutter

Description:

This cutter has a Tshaped head design, made of carbide with a welded cutting edge.

Application:

Primarily used for machining Tslots and deep grooves, ideal for connecting slots in machine parts, offering high strength and wear resistance.

Welded Carbide Chamfering Cutter Series

Description:

This tool features a specialized chamfering design, with a carbide edge welded onto the tool.

Application:

Used for chamfering workpieces and removing sharp edges or burrs. Chamfering cutters make the edges smoother, preventing cutting damage, and are widely used in mold manufacturing and metal processing.

Welded Carbide Center Drill Series

Description:

This drill has a sharp centerpoint design and is made with welded carbide for high hardness at the tip.

Application:

Commonly used for precise positioning and centerhole drilling, serving as a pilot tool for drilling. It accurately positions holes, preventing drill deviation in subsequent drilling, thus enhancing machining precision.

Welded Carbide Side Milling Cutter – Flat Cutter Series

Description:

This series has a flat design, made with carbidewelded edges specifically for side milling.

Application:

Suitable for largearea flat and side machining. Commonly used in processing large workpieces, such as molds and automotive parts, suitable for flattening surfaces or milling.

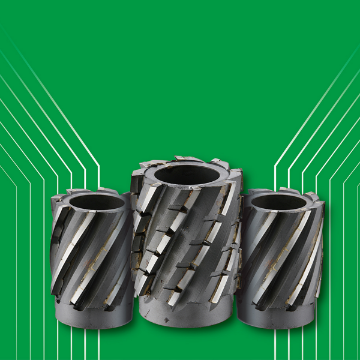

Welded Carbide Cylinder Cutter Series

Description:

This drill has a sharp centerpoint design and is made with welded carbide for high hardness at the tip.

Application:

Commonly used for precise positioning and centerhole drilling, serving as a pilot tool for drilling. It accurately positions holes, preventing drill deviation in subsequent drilling, thus enhancing machining precision.

Welded Carbide Dovetail Cutter Series

Description:

This cutter has a dovetailshaped head with a welded carbide edge, typically at a specific angle to adapt to dovetail machining.

Application:

Mainly used for dovetail slot machining, for sliding fits between components, ensuring solid connections. Suitable for dovetail joining in woodworking and metalwork.

Welded Carbide Milling Cutter Series

Description:

The welded carbide milling cutter has a highstrength cutting edge welded to the body, available in various shapes and sizes.

Application:

Used for multiple milling applications, including flat, side, and contour milling. Suitable for precise mold production and machine part processing, providing highprecision surface finishes.